The development of alternative drives for boats and yachts has been progressing rapidly for years. E-mobility on the water, especially in terms of environmental protection, is much talked about and is more topical than ever. More and more boats are now equipped with electric drives.

Advantages of Fischer Panda electric motors

Fischer Panda electric drives use modern and powerful e-motors. Electric motors are much quieter than combustion engines. They have no gearbox and are virtually silent and practically maintenance free.

The electric drive operates emissions free – preserving water quality, the environment and marine life within the area sailed. The motors feature permanent magnet technology and have an efficiency of up to 96%. They are brushless and have an integrated thrust bearing. The motors operate without sensors. They have the maximum torque throughout their entire speed range. Full torque is available from the first turn of the motor.

Operating the electric drive is simple and the motor is started by simply pressing a button. With a seamless power control, the boat’s speed can be easily regulated. It is also possible to switch between forward and reverse without shifting gears.

Although the electric motor is smaller and lighter than a conventional combustion engine, weight savings gained through the lighter electric motor are usually offset by the weight of the batteries.

In the conventional drive system, the diesel engine, gearbox, and propeller are coupled together via the drive shaft, which requires more space. Therefore, the installation location cannot be freely chosen.

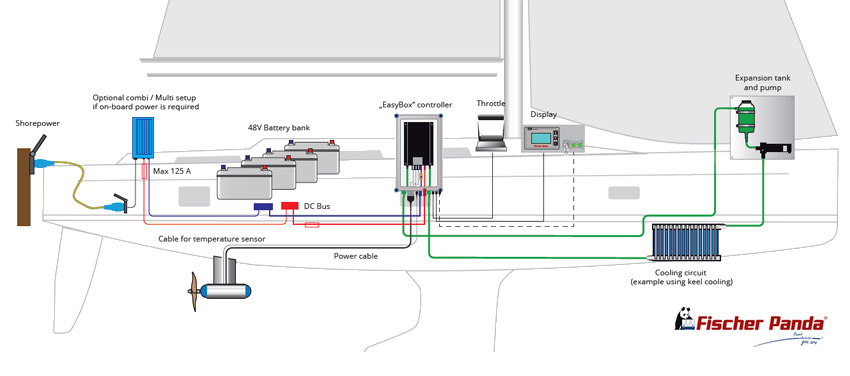

The main components of a Fischer Panda electric drive system are connected by electrical cables. Energy stored or temporarily stored in the battery bank is also supplied to the motor via cables. This provides greater flexibility for the installation and a better weight distribution, an individual installation layout is possible. This makes the system flexible and space-saving.

100% electrical cruising with Fischer Panda

With a battery-only system, cruising is practically silent allowing and allows those onboard to enjoy nature and tranquillity. This type of system is also an ideal choice for owners who wish to sail climate- neutrally or on waters where boats with combustion engines are prohibited.

The energy is stored in a powerful battery bank. The most common batteries used are AGM or lithium (iron phosphate) batteries. In most 100% electric systems, the battery bank is usually recharged using shore power connection when moored in the harbor.

If a fixed propeller is installed, it is possible to recuperate some of the energy while sailing. The propeller rotates the motor which in turn generates power. However, a minimum speed is required while sailing for this to work. The battery can be charged with about 10% of the actual power of the electric motor.

Other alternative methods of power generation for recharging the batteries can also be achieved using solar cells or wind power. This will also require additional power inverters or charge controllers to be installed.

Modern E-drive system from Fischer Panda can be installed on monohulls or multihulls requiring one or two drives. They consist of the following components:

- Electric drive motor (shaft, pod or parallel drive)

- Motor controller, fuses, power supply for cooling, etc.

- Battery bank (up to 20 kW system: 48 V DC, >20 kW – 100 kW: 420 V DC)

- Control unit incl. display (monitoring, setting and control of all functions)

- Throttle (single or double, depending on the number of drive motors)

- Optional: Battery charging setup

- Optional: Hybrid System with a diesel generator for battery charging and on-board power supply

A classic 48 V drive system can usually be installed in yachts with a displacement of up to 40 tons (2 x 20 kW). High-voltage systems (from 360 up to 420 V) are offered for yachts with a higher displacement.

Here are two examples of 48 V electric drive systems

1. Single Drive in Monohull

When sailing on sea, a 10 kW (48 V) drive system is sufficient for a monohull sailing yacht with a displacement of up to approx. 4 tons and a LOA of up to approx. 11 meters, in current-free waters a 10 kW (48 V) drive system is sufficient even for a displacement of up to approx. 10 tons and a LOA of up to approx. 14 meters.

2. Dual Drives in Multihull

A catamaran fitted with 2 drives of 10 kW each are sufficient up to a displacement of 8 tons and a LOA of up to approx. 14 meters.

Fischer Panda electric motors

Fischer Panda electric motors are very efficient and powerful, especially at lower speeds.

Fischer Panda electric motors are available with 1200 and 600 rpm. Motors with 1200 rpm are suitable for small propellers. Electric motors with 600 rpm can be used for large propellers. Large propellers with 600 rpm have a higher efficiency, i.e. better efficiency. Higher efficiency means lower energy consumption, i.e. higher range with the same battery capacity.

Fischer Panda supplies three versions of drives.

Primary drives are available as internally mounted shaft drives and external mounted (underwater) podded drives. Auxiliary drive versions function a parallel hybrid drive; this version is fitted to a main engine’s drive shaft.

Thanks to their robust and professional construction, Fischer Panda motors and system components are perfectly suited for various applications from recreational yachts to commercial use.

1. Fischer Panda Shaft Motors

Shaft motors are installed in the boat’s hull at an existing propeller shaft. They feature a double-walled, water-cooled aluminium housing with an integrated thrust bearing.

The motor drives the shaft to which the propeller is attached. Shaft motors can also be mounted in parallel with the main motor.

1.1 Fischer Panda Dual Motors

A combination of two electric motors (e.g. 2 x 20 kW, 600 rpm / 640 Nm) directly connected to the drive shaft is also possible. This design offers high redundancy and flexibility. Depending on the power requirement, one electric motor can be connected or disconnected. To further increase redundancy within the system, the motors can be powered by separate battery banks as needed.

Each drive motor contains two separate electrical windings and have their own control and throttle. The motors are connected to each other by a drive belt.

By means of a heat exchanger, the motors can also be cooled using a dual circuit setup with seawater.

2. Fischer Panda Podded Motors

These types of motor are fitted in a compact, watertight housing under the hull. Podded motors can be rotatably mounted on request.

They are made of stainless steel. Their 3-stage sealing provides maximum safety and minimum maintenance. The advantage is that underwater motors do not require additional cooling. They can be attached to an existing rudder or steering system. Brackets are available to attach the motors to different hull shapes.

The motors are submerged under water which means the remaining system components require little space inside the yacht.

The submersible motors are also available with a rudder/propeller protection.

2.1. Fischer Panda Podded Motors for Saildrive mounting plate

A Fischer Panda podded motor can also be fitted into yachts with saildrive mounting plate. It is possible to replace an existing diesel saildrive combination by an electric motor, which is a great advantage for the interior design.

Only the battery bank and motor control are installed in the hull. The podded motor is cooled by the surrounding water. The electrical connections to the motor winding lead through a centre tube on the drive.

The direct drive has no gearbox which results in low maintenance requirements and minimizes noise and vibration. There are also added advantages that there is no diesel smell or diesel and oil collecting in the bilge.

3. Alternative: Fischer Panda Parallel Hybrid Drives

Fischer Panda parallel hybrid drives are suitable for yachts fitted with a conventional drive system with combustion engine / gearbox. Parallel hybrid drives are ideal for cruising and manoeuvring at very low speeds.

They can often be operated in protected waters where the operation of a combustion engine is not permitted.

Parallel hybrid motors are easy to install, inexpensive and very quiet. The motor is mounted parallel to the existing drive shaft; no further modifications to the drive train are necessary.

By using permanent magnet motors, the hybrid drive motor can be used as a generator/alternator when the diesel engine is running.

An external alternator can use the entire speed range for charging the battery (even when not moving).

When the diesel engine is switched off, the yacht can be driven using the electric motor only.

A classic example of this system is a 100 HP diesel with a 10 or 20 kW parallel hybrid. In the “parallel hybrid drive”, the electric motor is connected in parallel with the drive shaft of the diesel drive motor.

The propeller is generally calculated for the performance of the diesel engine and is therefore too large for the electric motor. Since the power of the diesel engine and the electric motor are usually very different, the reduction (speed shaft / propeller to the electric motor) must be calculated. For an exact calculation, the propeller’s power curve is required.

The battery bank

Almost all battery types can be used in Fischer Panda propulsion systems e.g. traction batteries or lithium batteries. Lithium batteries are long-lasting, fast-charging, have more usable capacity and are lighter than lead-based AGM batteries. However, lithium batteries are more expensive.

A battery management system (BMS) protects lithium batteries from damage and charges each cell individually. For this reason, we always recommend certified lithium batteries with a BMS to protect them from overcharging and deep discharge.

AGM batteries are well-suited for small and medium-sized battery systems. They are less expensive. However, they are quite heavy and the capacity is not fully usable. Lead-acid batteries (AGM and gel batteries) should also be disconnected in winter and stored in a fully charged state if possible.

The battery charger

A suitable battery charger must always be used to recharge the batteries.

Charging from shore power or generator is possible by using an additional inverter. A multifunction inverter can manage battery charging, 230 V on-board power supply and shore charging in one unit while it automatically switches between two input sources (e.g. generator, shore power).

A DC/DC converter supplies energy that can be used for charging the starter batteries and for on-board system power supply (lights, navigation electronics, etc.).

Optional: Fischer Panda generators for battery charging and on-board power supply

For greater independence or as a safety backup a Fischer Panda diesel generator can be integrated into the electric propulsion system. This can be used to charge the battery bank efficiently, allow greater cruising ranges or provide power when anchored where a shore power connection is not available.

If the focus is on cruising, a powerful DC battery charging generator is recommended. This charges the battery bank directly. Excess power can be used for the electrical appliances on board if the boat is cruising at slower speeds. If no power is needed for the other consumers on board, the generator is available exclusively for charging the battery bank and functions as a range extender. A DC generator with the appropriate voltage is also suitable for many types of lithium batteries.

An AC generator is generally the better choice if the focus is on powering electrical equipment e.g. (240 V 50 Hz) on board.

The hybrid system supplies power to both the drive and the electrical consumers on board. This makes the battery bank and generator the central power source for both systems.

Fischer Panda generators are fitted within a sound insulation capsule which reduces operational noise levels. This ensures that you can continue to enjoy the peace and quiet. The sound insulation capsules are available as glass-reinforced plastic or metal versions with various amounts of insulation material.

Fischer Panda supplies everything from a single source, from planning to the design of the drive technology and the onboard current.